By Dealing with Opteco you GET MORE!

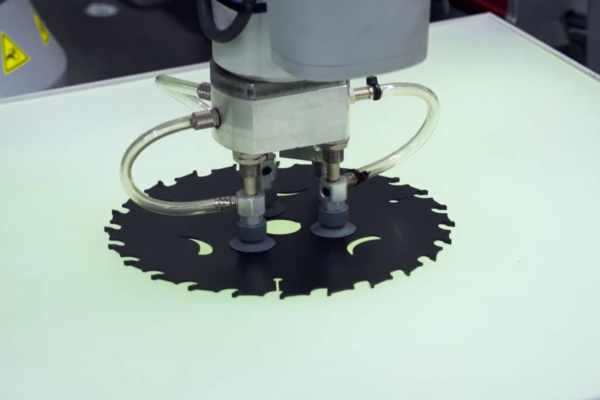

One of the most powerful services we offer to sawmills globally is our Optimisation Hub, a proven, data-driven approach to circular saw blade design that delivers real, measurable improvements on the mill floor.

Every sawmill is different and more importantly, every sawmill is constantly changing. Feed speeds adjust, timber species vary, applications evolve, and production targets shift. Through the Optimisation Hub, we begin by capturing detailed operational data around a specific machine, including: In-feed configuration, feed speeds, timber species, application type, cutting conditions, current performance challenges and more. We also work closely with the mill to identify their key pain points whether that’s throughput, recovery, finish quality, blade life, or overall cost per cubic metre.

All captured data is processed through Opteco’s Optimisation Hub calculator, a proprietary system developed from years of industry knowledge, R&D, and real-world results. This system analyses the full operating picture and allows our engineering team to design and draw a circular saw blade specifically for that sawmill and application. The result is not just a new design, it’s a purpose specific product engineered to outperform. Because the Opteco technical team design the blade based on real operating data, we can confidently stand behind the result and guarantee performance improvements.

Innovation is at the heart of everything we do at Opteco. With dedicated R&D equipment and experienced technical teams this allows us to partner with sawmills in order to get real tangible results. The Optimisation Hub creates a collaborative process where we partner with our customers to improve productivity, efficiency, and profitability. Once mills experience this approach, it quickly becomes an integral part of their ongoing operation.

One recent example is porta sawmill in Bombala, NSW, Australia. By redesigning their circular saw blade through the Optimisation Hub, porta sawmill achieved:

- An additional 1,000 logs per day through the sawmill

- Improved cut quality

- Extended blade service life

The impact was significant. With overheads remaining the same, processing an extra 1,000 logs per day meant higher output, and improved profitability. Porter Products is just one example. Opteco has partnered with sawmills across the globe, delivering consistent performance improvements through Optimisation Hub blade design. The results speak for themselves: higher throughput, better quality, longer blade life, and reduced operating costs. For many of our customers, it becomes a core part of how they run their business, with Opteco viewed not just as a supplier, but as a trusted technical partner.

If you’re looking to unlock the full potential of your sawmill, the Optimisation Hub is where data, innovation, and performance come together. Start speaking to our team today to see real tangible results and GET MORE by dealing with Opteco.